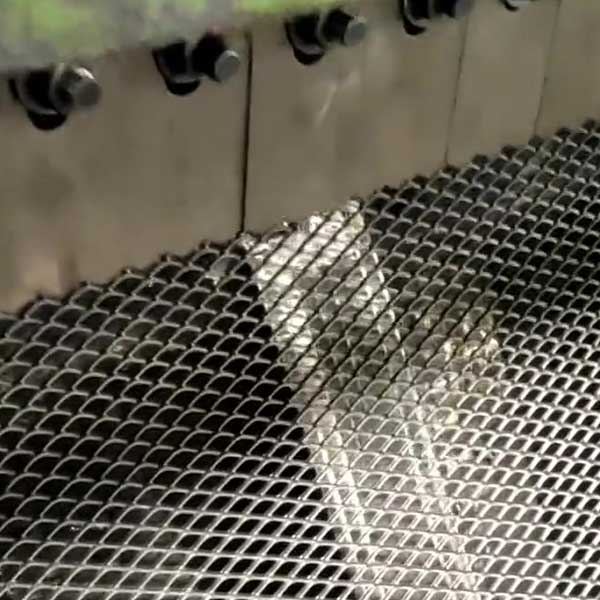

316 Stainless Steel Expanded Metal Mesh

- bellayingrui@gmail.com

- +8613611177086

- +8613611177086

Overview316 stainless steel expand metal meshare manufactured from high-quality 316 austenitic stainless steel through precision stamping or stretching processes. Inheriting the exceptional properties of 316 stainless steel, these sheets achieve a perfect balance of lightweight construction, h

Product details

Overview

316 stainless steel expand metal mesh are manufactured from high-quality 316 austenitic stainless steel through precision stamping or stretching processes. Inheriting the exceptional properties of 316 stainless steel, these sheets achieve a perfect balance of lightweight construction, high permeability, superior drainage, and decorative appeal through their unique mesh structure. They represent an ideal solution for demanding industrial environments and high-end applications.

Core Material Advantage: 316 Stainless Steel

316 stainless steel represents an upgraded version of 304 stainless steel. By incorporating approximately 2-3% molybdenum (Mo), its overall performance is significantly enhanced:

Exceptional Corrosion Resistance: Molybdenum substantially enhances resistance to chloride corrosion (e.g., seawater, chemical atmospheres), pitting, and crevice corrosion. Its corrosion resistance far surpasses 304 stainless steel, delivering outstanding performance in demanding conditions like marine environments and chemical processing.

Superior High-Temperature Performance: Exhibits enhanced creep resistance and oxidation resistance in elevated temperatures.

Superior Mechanical Properties: Offers excellent strength, toughness, and weldability, facilitating easy processing and forming.

Product Features and Advantages

Sturdy Structure, High Strength and Lightweight: The unique continuous mesh structure reduces self-weight while effectively distributing loads, delivering high mechanical strength and impact resistance.

Transparent and Aesthetic, Modern Appeal: Regular diamond, rectangular, or custom perforations provide excellent light transmission, ventilation, and visibility, blending functionality with contemporary industrial aesthetics.

Superior Drainage and Slip Resistance: Open mesh allows seamless passage of liquids, dust, and debris, while the surface offers natural slip resistance, ideal for platforms, walkways, filter elements, and more.

Easy to Process and Install: Can be cut, bent, welded, or hemmed for secondary processing, offering flexible and convenient installation.

Long Lifespan, Low Maintenance: Thanks to the stability of 316 stainless steel, the product has a long service life, requires virtually no maintenance, and offers low overall operating costs.

Typical Application Areas

Industrial and Chemical: Equipment protective covers, filters, vibrating screens, catalyst support mesh, pickling production lines, exhaust gas treatment equipment.

Marine and Shipbuilding: Ship gangway treads, anti-slip decks, marine platforms, seawater filtration systems, corrosion-resistant guardrails.

Environmental Protection and Energy: Wastewater treatment screens, waste sorting equipment, flue gas desulfurization tower internals, new energy battery drying mesh belts.

Construction & Decoration: Building curtain wall backing panels, safety guard nets, interior/exterior decorative grilles, stair treads, ventilation partitions.

Food & Pharmaceutical: Used in hygienic environments for drying racks, conveyor belts, etc. (requires appropriate surface treatment).

Key Technical Parameters (Customizable)

Material: 316

Common Aperture Shapes: Diamond, rectangular, hexagonal, etc.

Mesh Size: Long Wire Distance (SWD): Typically 1mm-100mm; Short Wire Distance (LWD): Typically 0.7mm-50mm.

Wire Thickness (Panel Thickness): Commonly 0.2mm - 6.0mm.

Surface: Typically supplied in natural stainless steel finish (matte). Polishing, sandblasting, electrolytic treatment, etc., available upon request.

Core Reasons for Selecting 316 Stainless Steel Wire Mesh

It transcends a basic wire mesh to deliver a high-performance, long-lasting, and versatile engineering solution. Choosing it means opting for unmatched reliability in harsh environments, structural design flexibility, and long-term cost-effectiveness.

We offer comprehensive services from standard specifications to customized solutions. Contact us for detailed technical documentation and tailored solutions.

Translated with DeepL.com (free version)