Stainless Steel Expanded Metal Mesh

Nickel expanded mesh is a type of metal mesh made from nickel that has been expanded to form a diamond-shaped pattern of openings. The expansion process involves cutting and stretching a flat sheet of nickel to create a mesh with a three-dimensional structure. Primarily used in demanding industrial fields like fuel cells and medical applications due to its specific properties.

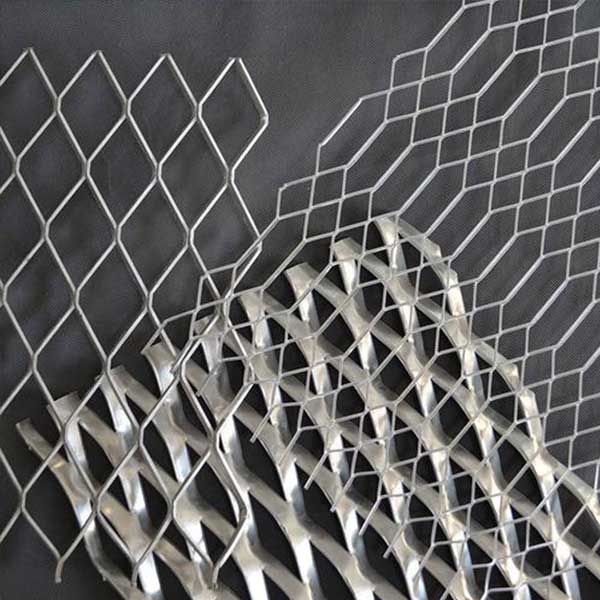

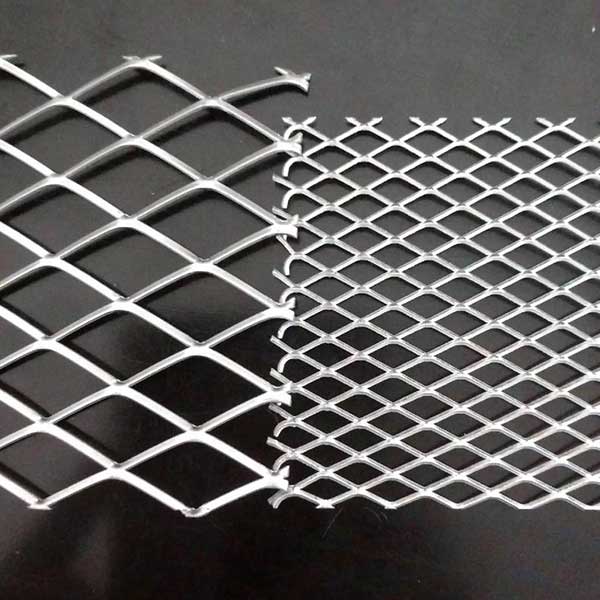

Mesh Type: diamond, hexagon

Surface type: raised or flattened

Features

Excellent high-temperature resistance: Expanded nickel mesh is indeed an excellent high-temperature resistant material, Generally, nickel-chromium alloy meshes can withstand much more extreme heat.

Good corrosion resistance: Expanded nickel mesh can offer good corrosion resistance.

High strength: Specialized processing methods, nickel materials can achieve significantly higher strength.

Long service life: Expanded nickel mesh can achieve a long service life, particularly due to nickel's inherent corrosion resistance.

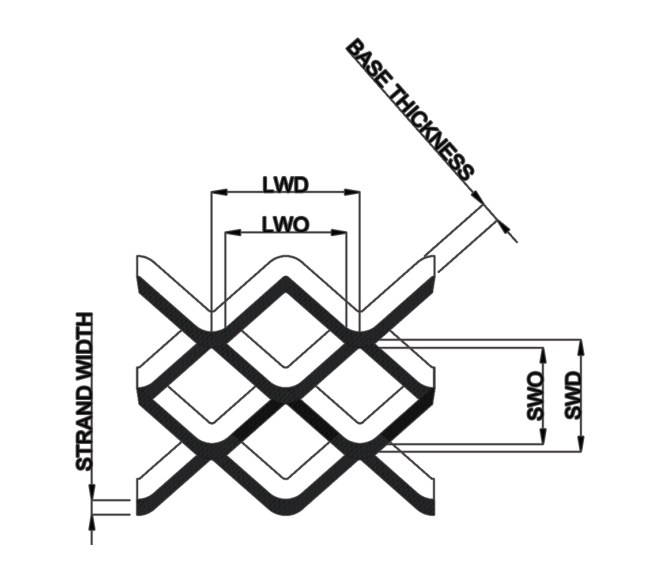

Specifications

NICKEL MESH (EXPANDED TYPE) | ||||||

OVERALL WIDTH (m) | OVERALL LENGTH (m) | LWD (mm) | SWD (mm) | SHEET THICKNESS (mm) | STRAND WIDTH (mm) | |

≤ 1.52 | ≤ 11.92 | 1.50 | 0.80 | 0.25 | 0.25 | |

1.60 | 0.80 | 0.05 | 0.10 | |||

2.00 | 1.00 | 0.10 | 0.15 | |||

2.00 | 1.00 | 0.25 | 0.25 | |||

2.00 | 1.00 | 0.30 | 0.35 | |||

2.50 | 1.50 | 0.20 | 0.25 | |||

4.00 | 2.00 | 0.40 | 0.45 | |||

6.00 | 3.00 | 1.00 | 1.20 | |||

SURFACE TREATMENT | NONE PLASMA SPRAY (50%ALUMINUM + 50% NICKEL) PLASMA SPRAY (20%ALUMINUM + 80% NICKEL) PLASMA SPRAY (80%ALUMINUM + 20% NICKEL) FLATENING IS AVAILABLE | |||||

Applications

Water electrolysis hydrogen industry: Electrolysis Cell Electrode, Catalyst Substrate, Industrial Electrolyzers.

Chemical power supply field: Energy Storage, Energy Conversion.

Chemical industry: Oil-Water Separation, Catalytic Reactions, Filtration, Electrode & Substrate.

Aerospace industry: used in the production of vacuum electrical parts, and electronic instruments.