What is the difference between SWD,SWO,LWD,andLWO

In this post, we’ll explore the different of the expanded metal mesh' SWD,SWO,LWD,andLWO—and explain how to choose the right spec for your application.

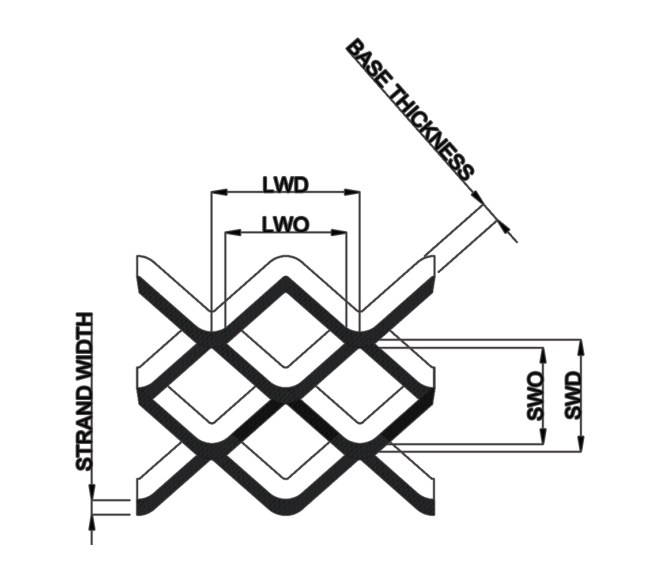

. LWD (Long Way of the Diamond)

LWD stands for “long way of the diamond,” referring to the length of the longer diagonal of each diamond opening. It is measured from the center of one node to the center of the next node along the long axis of the diamond. LWD is typically larger than SWD, since it’s the longer dimension of the diamond shape.

A larger LWD yields greater overall open area and can improve airflow or visibility through the mesh. But it can also make the mesh less flexible and more rigid along the long axis. Conversely, a smaller LWD (closer in size to the SWD) results in a more uniform, square-like opening and can enhance the mesh’s strength because the strands are closer together.

. SWD (Short Way of the Diamond)

SWD stands for “short way of the diamond.” This refers to the length of the shorter diagonal of each diamond-shaped opening, typically measured from the center of one node (intersection of strands) to the center of the adjacent node along the short axis of the diamond.

In simpler terms, it’s the short dimension of each opening including the material between nodes. A smaller SWD generally means a tighter mesh (more diamonds per area), which can increase the mesh’s flexibility in one direction and create a finer filtration screen. A larger SWD means the diamonds are elongated in the short direction, usually making the mesh slightly more rigid along that axis and reducing the number of openings per area. The SWD is critical for applications that need a certain mesh density or are concerned with how the mesh will flex or drape in the direction of the short diagonal.

Together, SWD and LWD define the basic geometry of the expanded mesh openings and are usually given in inches or millimeters. For example, an expanded metal spec might list SWD = 0.25″ and LWD = 0.50″ for a certain mesh pattern.

. SWO and LWO (Short Way of Opening, Long Way of Opening)

These terms refer to the clear opening size of the mesh. SWO is the short way of opening, meaning the distance between the inner edges of the strands along the short diagonal. LWO is the long way of opening, the distance between inner strand edges along the long diagonal.

In other words, SWO/LWO measure only the open gap, whereas SWD/LWD measure from center-to-center of nodes (including the material). For any given mesh, SWO is slightly smaller than SWD (by roughly one strand width), and LWO is smaller than LWD. These opening dimensions are very relevant for filtration and open area.

For example, if you’re designing a filter and need to block particles above a certain size, you would look at the SWO/LWO to know the actual free space a particle could pass through. Similarly, for applications like architectural screens or EMI shielding, SWO/LWO tell you how much light or electromagnetic waves can pass. Designers will specify SWO/LWO when the exact aperture size is critical to the function (whereas SWD/LWD are used for the overall mesh pitch including the strands).